Exploring the Role of Electric Actuators in HVAC Systems

Electric Actuators are very important for the operation and efficiency of HVAC systems because they provide exact control over the heating, ventilation, and air conditioning processes. These devices perform functions like regulating air flow, temperature, and pressure in residential and commercial buildings. As smarter building systems and energy-efficient solutions become necessary, the use of electric actuators in HVAC applications is becoming ever more significant. This article discusses the importance of electric actuators in HVAC systems, the benefits, and how working with a known control valve manufacturer improves system efficiency.

What Are Electric Actuators in HVAC Systems?

In an HVAC system, the productivity of an electric actuator is measured by the energy provided to the damper position to perform the mechanical involvement. The building determines how well the indoor atmosphere is controlled by the thoroughfare, pressure, and temperature balance worked on by these systems. The use of Electric actuators empowers the HVAC industry by enabling precise automation integration which contributes to energy savings and lower operational costs. They can also be actuators for globe valves, dampers, and other mixing boxes used to keep the system balanced and operating efficiently. An electric actuator operates efficiently and is composed of simple parts. The moment a control system transmits a signal overall, the actuator rotates the lever of the valve, or damper to the correct angle. The adjustment and position of the valve, and damper position rotates impacts the temperature alongside the airflow regulation to guarantee that the system works adequately. Among the most pressing benefits of electric actuators is attempting to automate reachable boundaries and power range control of more complex applications of HVAC systems. In addition, they can control different types of HVAC systems which makes it practical to control the environments precisely.

Advantages of Electric Actuators in HVAC Systems

The advantages of actuators in an HVAC system is far-reaching. They have the ability to increase energy efficiency, improve system performance, and even extend the life of the actuators. One of the key benefits is precise control. HVAC systems have precise parameters for both temperature and airflow, which needs to be thoroughly regulated to achieve comfort, and energy efficiency. Electric actuators allow precise settings concerning dampers and valves. This enables adjustment in real time, under the given operating conditions. This precision allows for active energy waste minimization, fully ensuring that the HVAC system is working just enough to meet the set parameters. Their energy usage is another highly appreciated quality. Electric actuators have a great deal of energy efficiency, especially when compared to pneumatic actuators, which are highly reliant on compressed air. Electric actuators, on the other hand, utilize power strictly when in motion, which is extremely beneficial in systems that commonly run continuously, such as those used in HVAC systems. Electric actuators also have the capability to enhance a system’s energy efficiency. Reduced operating costs and energy is less is a huge benefit to using electric actuators as well. They are also easier on the environment. In addition, electric actuators utilize greater energy efficiency, further reducing utility stress. Electric actuators also require less maintenance than any pneumatic or hydraulic alternatives. Their simple design with fewer active components decreases the likelihood of breakage and wear, making them a dependable component of an HVAC system operation for many years.

Electric actuators can manage more intricate and diverse tasks which provides more flexibility in system design and operation.

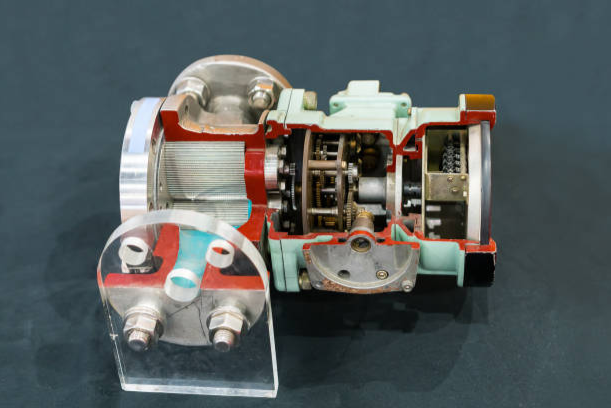

How Control Valves Operate with Electric Actuators

Electric actuators are frequently paired with control valves, for example actuated globe valves, in order to manage the flow of liquids and air in HVAC systems. A control valve is very important in HVAC applications because it has the assignment of controlling water, air, or refrigerant, depending on the system’s needs. In an HVAC system, the actuator is responsible for adjusting the position of the valve to either open or close it, depending on the needs of the system. The combination of the control valve with an electric actuator makes it possible to perform automated regulation of different parts of the HVAC system. In an air handling unit, for example, the actuator may reposition a damper as directed by a building management system (BMS) that controls indoor air, temperature, or humidity. Automating these functions assists the HVAC system to adapt to prevailing conditions with the least amount of human assistance. Smooth integration of electric actuators and control valves contributes to the flexibility ensuring that the HVAC system is operated as efficiently as possible. Using a reputable control valve manufacturer ensures that the electric actuators fit perfectly with the control valves installed within your HVAC system to maximize efficiency and reliability.

A competent producer will help you with actuator and valve selection so that the components you choose are designed for your system.

Read Also: Industrial Magnetic Tools Revolutionizing Modern Manufacturing

The Podium of Electric Actuators in HVAC Systems

As electric actuators evolve in tandem with building automation systems and energy consumption trends, they will remain pivotal for climate control in buildings. The application of smart technologies such as artificial intelligence (AI) and machine learning will further enhance the capabilities of electric actuators by enabling them to make decisions using real time data. For example, actuators could control radiators, valves, and dampers not only by preset points but also by predicting energy requirements or analyzing the occupancy of the buildings. Alongside the enhancement of system performance, electricity actuators will also be instrumental in the achievement of sustainability targets. With the world striving for green buildings and energy-efficient systems, electric actuators will facilitate HVAC systems for compliance and reduced carbon emissions. By increasing energy efficiency, reducing maintenance, smart system integration, and sustainability, these electric actuators will be crucial for the future of HVAC technology. An electric actuator’s abilities encompass the constant need for improvement with technology integration. Hence, an electric actuator will always remain in the sphere of innovation.

These actuators will advance with technology, further meeting challenges posed by modern buildings through control, customization, and operational intelligence.

Conclusion

In modern energy-efficient and sustainable HVAC systems, electric actuators have emerged to be pivotal controllers. Their capability of controlling airflow, temperature, and pressure within a building makes them vital for achieving and maintaining comfortable conditions in buildings. A reputable control valve manufacturer’s collaboration guarantees proper operation with optimal energy efficiency and lowered operating costs. Advanced technology in HVAC systems combining electric actuators with actuated globe valves or other control elements enhances performance. With the advancement of technology, the energy efficient operations of the future will depend on electric actuators due to their primary role in HVAC systems. Their contribution to automation, energy saving, and increased system reliability will continue to drive the change in HVAC systems around the globe.