The Future of Pharmaceutical Packaging: Integrating Pill Counter Machines with Freeze Dryers

The pharmaceutical sector is always on the move to accommodate the latest technology and customer needs for quality, productivity, and accuracy. Pharmaceutical packaging is one of those areas that is undergoing dramatic changes. The combination of pill counter machines and freeze dryers is proving to be a revolutionary step towards enhanced quality control in packaging. Together with other innovations such as pill capsule fillers and pill presses, this technology will most likely usher the next phase of advancements in pharmaceutical production.

The Importance of Pill Capsule Fillers in Pharmaceutical Packaging

Pill capsule fillers are machines that are very important in the accurate and efficient capsule formulation dosage forms. These machines are critical in any pharmaceutical firm because they control capsule content uniformity. Nowadays, pill capsule fillers are also suitable for practically all dosage forms including powders and liquids, and advanced technology has made them more efficient.

As the pharmaceutical field slowly adjusts toward custom-tailored medicine, fillers for medicinal pill capsules are becoming more sophisticated. They can be designed to create various forms of medicine which can be tailored seamlessly to the patient’s conditions. For example, these fillers, alongside pill counter machines, can further enhance the level of automation which reduces the time taken and chances of human error. From the filler technology, pharmaceutical production can be further deviated to customize for greater market needs as said companies would find it easier to fulfill the ever demanding market needs.

These machines also bring another level of hygiene and safety by reducing human involvement in the filling process which helps reduce chances of contamination, especially when dealing with highly sensitive medications. Moreover, the volumetric and qualitative production capability of capsule fillers allows pharmaceutical companies, whether small or big, to meet these sets of demands without placing quality at risk. This shift in the market will steadily rise with the increase in demand for both targeted and generic medication – and with it, so will the reliance on these machines.

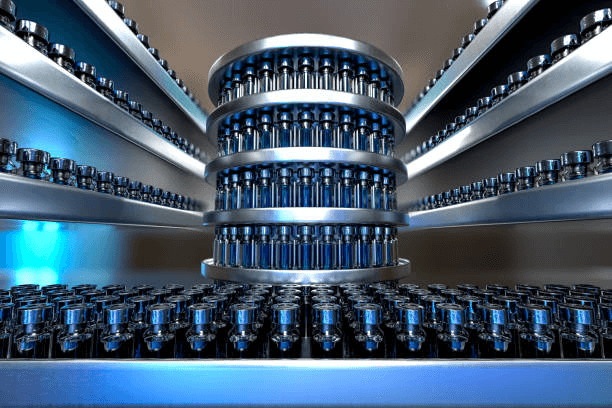

Merging Pill Counter Machines and Freeze Drying Technology

The merger of pill counter machines and freeze dryers is an important improvement in the integrating packaging systems. Freeze drying, or lyophilization, is a common process employed to keep the essential elements of a drug intact, particularly for biologics and vaccines. It makes the medication storable by getting rid of the water contained in the drug. Freeze drying works by residual moisture, ensuring that the medicine retains its effectiveness during that period of time before being used.

The latest technology in pill counter freeze dryers improves productivity in pharmaceutical packaging systems. Automatic counters can be programmed to accurately determine the total number of pills or capsules, effectively removing the need to be manually counted and packaged. Moreover, the freeze dryer preserves the medication’s potency while storing it. This combination leads to greater precision, the reduction of human error, and the optimum order of procedures in the pharmaceutical packaging systems. In addition, it enhances economic operational performance by improving the regulation of business processes because it facilitates management of inventory and eliminates the effects of excess stock or insufficient supply.

Because maintaining product integrity is vital, this sophisticated machine features updated control of the packaging workflow. By ensuring the correct dose is present in each pack as well as the stability of the freeze-dried medications, pharmaceutical companies can ensure the reliability and safety of their products. As the market for temperature-sensitive medications grows, the combination of pill counter machines and freeze dryers will undoubtedly become commonplace in pharmaceutical packaging lines.

The Important Role of Newer Pill Presses, Innovations in the Industry

Pill direct compression machines are used to produce tablets and capsules from granular materials, serving various purposes such as shoring or controlling the release of medication. With the increasing focus on tailored medicines, pharmaceutical companies have developed more sophisticated forms of pill presses that are able to create numerous dose sizes into the exact prescribed form. These machines increase the dosage accuracy of the tablets and also improve manufacturing and production by minimizing the effort and time spent in constructing tablets manually.

The effectiveness of modern pill presses means that they are capable of developing tablets with different coatings, which is vital in managing the release of the active ingredient to enhance the efficacy of the medicine. Through aiding in the production of multi-layered pills, pill presses facilitate the creation of complex medications that need to be released over prolonged periods of time or at particular sites in the human body. This is especially relevant for chronic illnesses that necessitate constant care and treatment.

Pill presses, together with pill capsule fillers, also increase the productivity and efficiency of cost in pharmaceutical manufacturing. Their advanced technology is of such high precision that each tablet is shaped exactly the same, guaranteeing dosages. With the A industry moving towards more inclusive therapies and complex delivery methods, it is certain that the contribution of pill presses in drug manufacturing will intensify.

How Automation and AI Improves Productivity

The pharmaceutical sector is moving towards Automation when it comes to the future of its pill and capsule packaging processes. The incorporation of automation in production lines, which has already been done to help improve work efficiency, is anticipated to continue increasing in significance. The conjunction of pill presses, pill counter machines, and freeze dryers creates an automated environment in which a considerable amount of sophisticated tasks can be accomplished with minimal human input. With these improvements, the processes also become more efficient, less expensive, and shorter in duration for new drugs.

Automation guarantees the elimination of guesswork and mistakes in the pharmaceutical packaging process. Software controlled pill counter machines, freeze dryers, and various other pieces of equipment, can help pharmaceutical firms create a production line that greatly reduces errors while increasing productivity. Given the increasing concerns within pharmaceutical companies to be compliant to stringent regulations, this integration of enhanced automation within the system is critical if such companies are to maintain high volumes of production.

Moreover, artificial intelligence (AI) is starting to play an essential role in pharmaceutical packaging. An AI-powered quality assurance system is capable of supervising capsule filling, freeze-drying, and even pill counting. Such automated systems help organizations to instantly resolve quality issues during production. Additionally, AI can assist pharmaceutical firms in production schedule optimization, trend tracking, and improving overall efficiency as a result of informed decisions.

The Future of Pharmaceutical Packaging

The possibilities concerning the future of pharmaceutical packaging are astonishing. It is expected that the use of pill counting machines, freeze-dryers, pill capsule fillers, and pressers in conjunction with automated robotics will allow pharmaceutical companies to meet the demand of high-quality and efficient packaging. What this means is better medication for patients and more streamlined operations for pharmaceutical companies.

With the recent advances in technology along with the ever increasing medicines and treatments is constantly emerging, the adoption of these advanced machines will change the methods through which drugs are produced and packaged. The combination of these technologies will boost productivity while ensuring the safety and quality of the products. Furthermore, with the growing dependence of pharmaceutical companies on precision medicine and more personalized drugs, these alterations will allow them to be more responsive to market needs.

In conclusion, the integration of pill counter machines with freeze dryers, along with advancements in pill capsule fillers and pill pressers, is shaping the future of pharmaceutical packaging. These innovations are set to benefit the entire heath industry, cut down production costs, and maintain stringent quality measures for pharmaceutical packaging. The days ahead appear to be bright with endless opportunities.